Entering Huludao Power Equipment

About Us

Renowned nationwide as a backbone designated large-scale enterprise for manufacturing large power transformers

Honor and Qualification

China National Key High tech Enterprise

Development History

Understanding the Over 50 Years of History of Huludao Power Equipment

Corporate Culture

The power equipment professionals of the new era will work together with you to achieve great success and move forward hand in hand

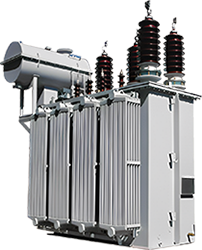

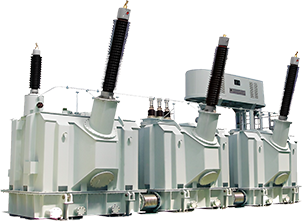

Our products

Excellent quality, internationally leading level

No data